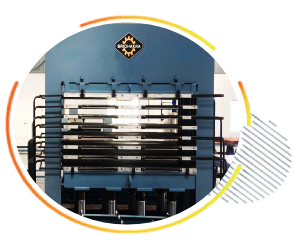

Veneer/Laminate Bonding Press

A veneer laminate bonding press (also called a laminate press or veneer press) is a machine used in woodworking and panel manufacturing to bond thin sheets of veneer or laminate to a substrate (like plywood, MDF, particle board, or solid wood) under controlled heat, pressure and time. These presses are essential in furniture, cabinet, door and decorative panel production where a high-quality durable surface finish is required.

Our presses produce a strong, smooth, defect-free bond. There are two types of Veneer/ Laminate Bonding Press which we manufacture at Srichakra.

Hot Press

Uses heated platens. Best for heat-activated adhesives. Produces faster and stronger bonds.

Tonnage | Platen Size | Daylight |

| 150 | 8×4 | Upto 5 |

| 200 | 10×4/10×5 | Upto 5 |

Cold Press

Applies pressure without heating. Used for adhesives that cure at room temperature. Lower energy use but longer cure times.

|

Tonnage |

Platen Size |

|

50/100/150 |

8×4 |

|

150/200 |

10×4 |